Aluminum Machining Services

Aluminum is particularly easy to shape and recycle, making it one of the most popular material choices for CNC machining. This material is malleable and durable, offering longevity while still being lightweight. At McCormick Industries, we utilize Swiss-style turning centers to achieve incredibly precise tolerances. Our aluminum machining services are highly efficient and cost-effective thanks to the use of live tooling and multi-axis machining.

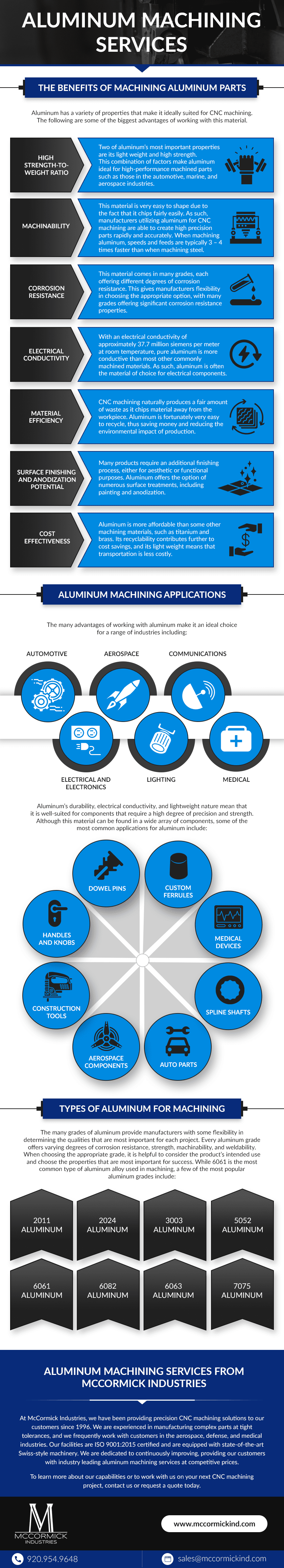

Benefits of Machining Aluminum Parts

Aluminum has a variety of properties that make it ideally suited for CNC machining. The following are some of the biggest advantages of working with this material.

Two of aluminum’s most important properties are its light weight and high strength. This combination of factors make aluminum ideal for high-performance machined parts such as those in the automotive, marine, and aerospace industries.

This material is very easy to shape due to the fact that it chips fairly easily. As such, manufacturers utilizing aluminum for CNC machining are able to create high precision parts rapidly and accurately. When machining aluminum, speeds and feeds are typically 3 – 4 times faster than when machining steel.

This material comes in many grades, each offering different degrees of corrosion resistance. This gives manufacturers flexibility in choosing the appropriate option, with many grades offering significant corrosion resistance properties.

With an electrical conductivity of approximately 37.7 million siemens per meter at room temperature, pure aluminum is more conductive than most other commonly machined materials. As such, aluminum is often the material of choice for electrical components.

CNC machining naturally produces a fair amount of waste as it chips material away from the workpiece. Aluminum is fortunately very easy to recycle, thus saving money and reducing the environmental impact of production.

Many products require an additional finishing process, either for aesthetic or functional purposes. Aluminum offers the option of numerous surface treatments, including painting and anodization.

Aluminum is more affordable than some other machining materials, such as titanium and brass. Its recyclability contributes further to cost savings, and its light weight means that transportation is less costly.

Aluminum Machining Applications

The many advantages of working with aluminum make it an ideal choice for a range of industries including:

- Automotive

- Aerospace

- Communications

- Electrical and Electronics

- Lighting

- Medical

Aluminum’s durability, electrical conductivity, and lightweight nature mean that it is well-suited for components that require a high degree of precision and strength. Although this material can be found in a wide array of components, some of the most common applications for aluminum include:

- Dowel pins

- Custom ferrules

- Medical devices

- Spline shafts

- Auto parts

- Aerospace components

- Handles & Knobs

- Construction tools

Types of Aluminum for Machining

The many grades of aluminum provide manufacturers with some flexibility in determining the qualities that are most important for each project. Every aluminum grade offers varying degrees of corrosion resistance, strength, machinability, and weldability. When choosing the appropriate grade, it is helpful to consider the product’s intended use and choose the properties that are most important for success. While 6061 is the most common type of aluminum alloy used in machining, a few of the most popular aluminum grades include:

- 2011 Aluminum

- 2024 Aluminum

- 3003 Aluminum

- 5052 Aluminum

- 6061 Aluminum

- 6082 Aluminum

- 6063 Aluminum

- 7075 Aluminum

Aluminum Machining Services From McCormick Industries

At McCormick Industries, we have been providing precision CNC machining solutions to our customers since 1996. We are experienced in manufacturing complex parts at tight tolerances, and we frequently work with customers in the aerospace, defense, and medical industries. Our facilities are ISO 9001:2015 certified and are equipped with state-of-the-art Swiss-style machinery. We are dedicated to continuously improving, providing our customers with industry leading aluminum machining services at competitive prices. To learn more about our capabilities or to work with us on your next CNC machining project, submit your inquiry using the form below:

"*" indicates required fields

Capabilities