Precision Thread Cutting Services

At McCormick Industries, we provide precision thread cutting services as part of our broader service portfolio. We’ll evaluate your individual requirements and work with you to manufacture threaded parts that provide desirable and consistent results. To ensure our clients receive the best services and products, McCormick Industries is backed by an ISO 9001:2015-certified quality management system with a specialization in precision machined parts. We offer a wide selection of machining services, including precision threading, CNC milling and turning, and Swiss machining for applications in need of the highest levels of precision.

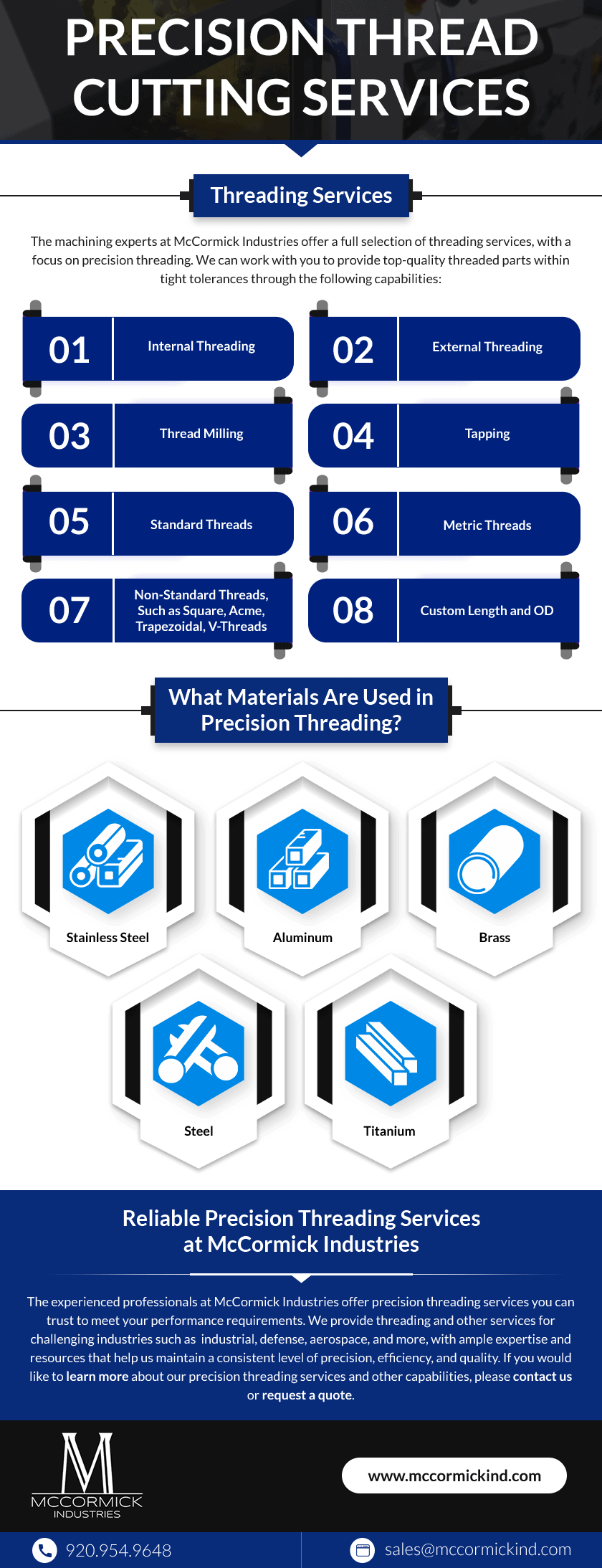

Threading Services

The machining experts at McCormick Industries offer a full selection of threading services, with a focus on precision threading. We can work with you to provide top-quality threaded parts within tight tolerances through the following capabilities:

- Internal threading

- External threading

- Thread milling

- Tapping

- Standard threads

- Metric threads

- Non-standard threads (square, acme, trapezoidal, V-threads)

- Custom length and OD

We use optical comparators, thread gages, and pitch micrometers to verify precision.

What Materials are Used in Precision Threading?

The ideal material for a threaded part will largely depend on the specifics of the application. When selecting the right material for precision threading, numerous factors including weight, strength, temperature requirements, and chemical and corrosion resistance properties should be considered. Some of the most popular materials for precision threading include:

- Stainless Steel: If you require parts with high corrosion and chemical resistance, stainless steel presents an optimal choice. Certain grades of stainless steel are also suitable for applications involving extreme temperatures.

- Aluminum: Aluminum is typically used for applications requiring lightweight parts with a favorable strength-to-weight ratio.

- Brass: Brass has excellent machinability and is often used for threaded couplings and fittings where there is a need for a low friction coefficient and high corrosion resistance.

- Steel: Steel is typically used in industrial applications and is valued for its strength and durability.

- Titanium: Titanium makes an ideal material for creating strong and lightweight threaded parts.

Internal vs. External Threading

The team at McCormick Industries can provide internal and external threading for parts. Through the use of internal and external threads, parts benefit from improved stability while enabling easier disassembly. As you would expect, internal threads reside inside the parts, which include certain types of nuts such as half, round, coupling, square, and hex nuts. External threaded parts include different types of bolts, studs, screws, and various fittings. Having a combination of these parts can contribute more structural integrity for threaded parts and the assemblies that use them.

Reliable Precision Threading Services at McCormick Industries

The experienced professionals at McCormick Industries offer precision threading services you can trust to meet your performance requirements. We provide threading and other services for challenging industries such as medical, industrial, defense, aerospace, and more, with ample expertise and resources that help us maintain a consistent level of precision, efficiency, and quality. If you would like to learn more about our precision threading services and other capabilities, submit your inquiry using the form below:

"*" indicates required fields

Capabilities