Machining processes such as precision turning use a wide range of materials to form standalone parts or components of machinery. Various metals and plastics offer different properties that affect the functionality of the final product; however, these properties can impact how a certain material responds to the turning process. In this blog post, we’ll cover the benefits and features of different materials and how they react to the turning process.

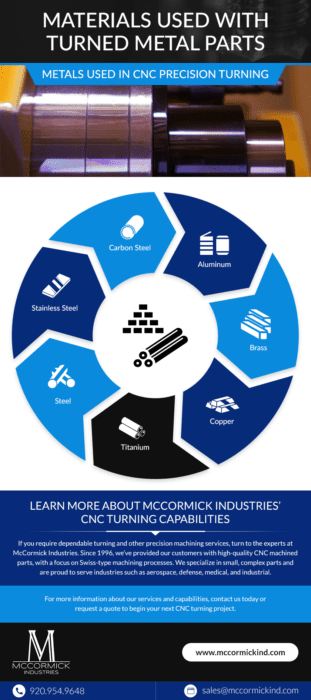

Metals Used in CNC Precision Turning

CNC precision turning often uses metal alloys for creating parts and products. Different factors determine which metal is suitable for the application, including the available budget for a project, the required properties of the completed part, and the metal’s compatibility with the precision turning process. Some of the metals used for precision turned parts include:

Aluminum

Aluminum is often used in precision turning because it is lightweight, non-magnetic, inexpensive, corrosion-resistant, and easy to machine. Aluminum machining allows for tight tolerances even for complex or intricate parts. Aluminum can also be plated with other materials to increase its conductivity and hardness, providing a less expensive alternative to copper, steel, or stainless steel.

Brass

Brass is a very cost-effective material choice for precision turned components that don’t require high levels of strength. Brass machining comes with a variety of benefits, including a clean finish, easy machining, and well-held tolerances and threads. This metal is ideal for use in more complex parts that include sophisticated details; however, it’s not suitable for vacuum applications or semiconductor products because of its tin and zinc content.

Copper

Copper is a more expensive but versatile choice for CNC precision turning. This metal is naturally corrosion-resistant, electrically conductive, and nonmagnetic. Copper responds well to precision turning; however, it does not hold tolerances as well as other metals such as aluminum. This metal is a great choice for hardware components and electric parts.

Titanium

Titanium is a very popular option for precision turning due to its heat resistance, corrosion resistance, and significant strength-to-weight ratio. Additionally, titanium is lightweight, biocompatible, and inert, making it suitable for various applications ranging from medical components to aviation parts. However, the downsides of titanium include its higher price and difficulty to machine.

Steel

Many manufacturers use steel for its durability and strength. The properties of steel alloys depend on the specific grade, and different alloying elements increase the material’s overall machinability. Some specific uses for steel materials include industrial applications, oil & gas, and automotive manufacturing. However, this metal is vulnerable to corrosion without plating.

Stainless Steel

Stainless steel is a desirable material option for CNC precision turning due to its corrosion resistance and strength. It also offers an attractive appearance and retains its durability, making it an ideal choice for consumer, commercial, and medical products. However, its strength and hardness often make stainless steel machining more challenging.

Carbon Steel

Carbon steel features higher carbon levels that contribute to its particularly hard and durable nature. Carbon steel can be machined; however, its machinability decreases with the increased hardness of each carbon steel grade. Following the production process, carbon steel is highly damage-resistant, dimensionally stable, and maintains its characteristics when exposed to high temperatures.

Other Materials Used for Turned Precision Parts

In addition to metal materials, certain plastics are compatible with precision turning processes for a wide range of products and components. These include:

Basic Plastics

Basic plastics offer an inexpensive alternative to metals and conductive materials. Many industries use basic plastics as they are inert and can be modified to fit various properties. Plastic machined parts are used in a wide range of industries including electronics, medical, industrial, and more.

Engineering Plastics

Engineered plastics have become increasingly popular in many applications over the years, as they offer many of the same strengths as their metal counterparts. They can be made with various enhanced properties, making engineered plastics a common alternative to aluminum and quarts in semiconductor applications. They can also self-lubricate and are easy to clean, making them ideal for medical instruments.

Learn More About McCormick Industries’ CNC Turning Capabilities

If you require dependable turning and other precision machining services, turn to the experts at McCormick Industries. Since 1996, we’ve provided our customers with high-quality CNC machined parts, with a focus on Swiss-type machining processes. We specialize in small, complex parts and are proud to serve industries such as aerospace, defense, medical, and industrial.

For more information about our services and capabilities, contact us today or request a quote to begin your next CNC turning project.