At McCormick Industries, we have been manufacturing and providing precision pins since 1996. Our precision pin manufacturing services offer high-quality, cost-effective solutions for customers for the aerospace, automotive, electronics, mining, plumbing, and other industries.

At McCormick Industries, we have been manufacturing and providing precision pins since 1996. Our precision pin manufacturing services offer high-quality, cost-effective solutions for customers for the aerospace, automotive, electronics, mining, plumbing, and other industries.

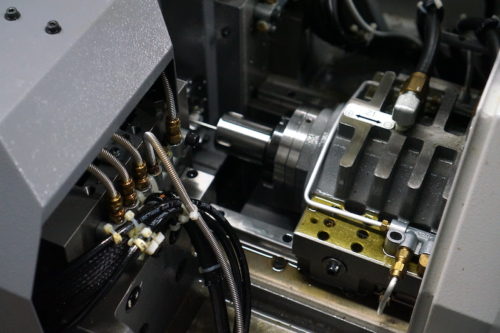

Our technologically advanced manufacturing facility and machinery include several Swiss-style turning centers with a range of capabilities. Our equipment operates on up to nine axes, enabling us to create the pin you require to exacting specifications. At McCormick Industries, our Swiss-style turning capabilities allow our team to manufacture your precision component with ultra-precise tolerances of ±0.0001 in.

We manufacture a wide range of pin types, including dowel pins, clevis pins, and swage pins. These machined pins are manufactured from a variety of materials. Our highly skilled team also can create custom elements, including chamfer ends, custom diameters, lengths, and finishes.

Industrial Pin Manufacturing Capabilities

Our state-of-the-art facility and technologically advanced pin manufacturing equipment enable us to produce pins in custom lengths and diameters. We custom manufacture pins with dual radius ends, a radius on one side, and a chamfer on the other, or dual chamfers.

At McCormick Industries, we can produce pins from various materials, including specific alloys required to meet MIL-SPEC, aerospace, or other industry standards. In addition to manufacturing your pin with a custom finish, we also can produce your component with an optional micro-finish, customized Rockwell hardness, and offer secondary features, such as milled flats, internal and external threads.

Custom Pin Capabilities

At McCormick Industries, we provide clients with custom pins manufactured to the specific length, diameter, type of material, and other features, to meet their needs. Our team understands that every application has unique challenges and requirements, and we work with our clients to create the perfect solution for their unique application.

At McCormick Industries, we provide clients with custom pins manufactured to the specific length, diameter, type of material, and other features, to meet their needs. Our team understands that every application has unique challenges and requirements, and we work with our clients to create the perfect solution for their unique application.

We are ISO 9001:2015 certified. Our capabilities include holding ultra-precise dimensional tolerances to ±0.0001 in. on our Swiss lathes. At McCormick Industries, we machine a variety of pin types, including but not limited to:

- Custom Dowel Pin

- Clevis Pin

- Swage Pin

- Taper Pin

- Firing Pin

- Slotted Spring

- Grooved Pin

- Bridge Pin

Pin Manufacturing FAQ

Here are the most frequently asked questions about pin manufacturing:

What are the different types of pins manufactured at McCormick Industries?

At McCormick Industries, we specialize in manufacturing several types of pins including:

- Dowel pins

- Clevis pins

- Swage pins

- Taper pins

- Bridge pins

What are dowel pins for?

Dowel pins are cylindrical metal rods that combine two pieces of wood or other materials. The dowel pin is inserted into a hole drilled in one piece of material, and the other piece is then placed over the dowel pin so that the two pieces are joined together. Dowel pins can also be used to align two pieces of material so that they are flush with each other.

Dowel pins are commonly used in woodworking but can also be used in other applications such as metalworking and plastics. Dowel pins are available in a variety of sizes, and the size you use will depend on the application. For example, a small dowel pin can be used to join two pieces of wood together, while a larger dowel pin can be used to align two pieces of metal.

What is a clevis pin?

A clevis pin is a type of fastener used to join two pieces of metal or other material. It consists of a small rod with a head at one end and a split ring at the other. The ring fits over a tab on the other piece of material, and the pin is inserted through holes in both pieces. The pin is then secured in place with a cotter pin.

Clevis pins are used in a variety of applications, including automotive and machinery assembly, plumbing, and electrical work. They are often chosen for their strength and durability, as well as their ease of installation and removal.

What is a swage pin?

Swage pins have a grooved or ribbed surface and are used to hold parts together by swaging or deforming the pin to create a tight fit. They are often used in industries such as construction, manufacturing, and mining, where high vibration or other external forces may cause parts to loosen.

What is a taper pin?

As the name suggests, taper pins have a tapered shape and are used to secure parts by wedging them in place. They are often used in machinery and other mechanical devices, as well as in industries such as woodworking and aerospace. Taper pins are typically made from strong, durable materials and are inserted into tapered holes for a secure fit.

What is a bridge pin?

Bridge pins are small, cylindrical pins that are used in stringed musical instruments such as guitars and mandolins to hold the strings in place on the bridge. They are typically made from materials such as ebony, rosewood, or plastic, but can be made of metal as well, and have a small hole at one end for the string to pass through.

What materials do we use in the machining of pins?

Our pin manufacturing capabilities at McCormick Industries enable us to produce the highest quality parts and components possible from various materials, including:

- Aluminum

- Brass

- Bronze

- Carbon steel

- Copper

- Plastics

- Stainless steel

- Steel

- Tool steel

- Titanium

- Exotic alloys

Contact McCormick Industries

At McCormick Industries, we are dedicated to providing our clients with the highest quality precision parts possible. Our state-of-the-art CNC pin machining facility is equipped with the most technologically advanced equipment available. Our experience as a clevis, swage, and dowel pin manufacturer has earned us the reputation for being a leader in the industry and made us uniquely qualified to produce small, complex parts for various sectors, including industrial, aerospace, defense, and medical.

Our highly skilled and trained professional staff is focused on continual improvement. We strive to provide our clients with the parts they need at competitive pricing. Additionally, we offer high quality, dependable components to our customers using the most cost-effective manufacturing processes available.

Our Swiss-style turning capabilities at McCormick Industries result in extremely fast cycle times — as low as 10 seconds — enabling us to manufacture large quantities of parts and components quickly – perfect for your precision medical machining needs. CNC technology and automated processes for bar feeding and part handling allow our machinery to operate unattended for extended periods lowering the production and labor costs associated with your component.

If you need custom pins manufactured to your specific length, type of material, diameter, and other requirements, then contact McCormick Industries today. We will be happy to provide you with a quote for your project.