Types of Precision CNC Machining

Leave a Comment

Using computer numerical control (CNC) technology, precision CNC machining removes excess raw material from a workpiece to create a functional finished product. CNC machining services are necessary to create precision machined components for nearly every industry, including automotive, aerospace, medical, and electronics.

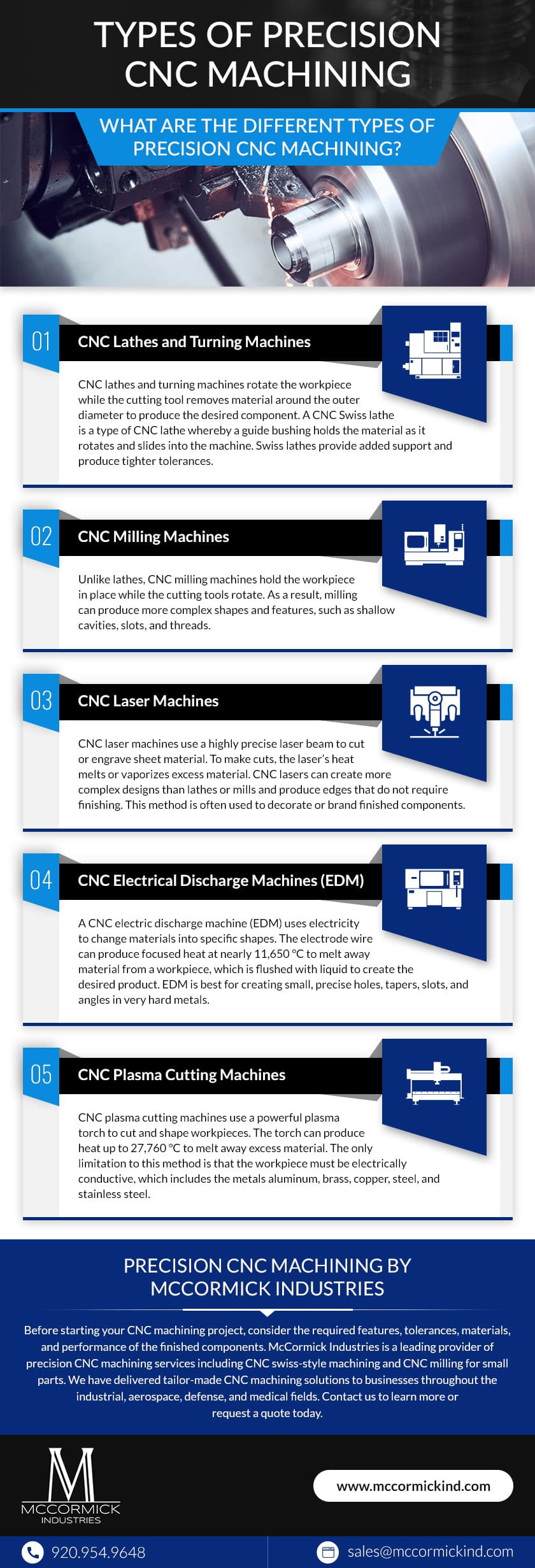

To determine which service is right for you, learn more about the five main types of CNC machining.

What are the Different Types of Precision CNC Machining?

Different machines perform different types of CNC precision machining. But every CNC machine can be programmed to achieve specialized features and tight tolerances that are not possible through conventional machining.

CNC Lathes and Turning Machines

CNC lathes and turning machines rotate the workpiece while the cutting tool removes material around the outer diameter to produce the desired component. A CNC Swiss lathe is a type of CNC lathe whereby a guide bushing holds the material as it rotates and slides into the machine. Swiss lathes provide added support and produce tighter tolerances.

CNC Milling Machines

Unlike lathes, CNC milling machines hold the workpiece in place while the cutting tools rotate. As a result, milling can produce more complex shapes and features, such as shallow cavities, slots, and threads.

CNC Laser Machines

CNC laser machines use a highly precise laser beam to cut or engrave sheet material. To make cuts, the laser’s heat melts or vaporizes excess material. CNC lasers can create more complex designs than lathes or mills and produce edges that do not require finishing. This method is often used to decorate or brand finished components.

CNC Electrical Discharge Machines (EDM)

A CNC electric discharge machine (EDM) uses electricity to change materials into specific shapes. The electrode wire can produce focused heat at nearly 11,650 °C to melt away material from a workpiece, which is flushed with liquid to create the desired product. EDM is best for creating small, precise holes, tapers, slots, and angles in very hard metals.

CNC Plasma Cutting Machines

CNC plasma cutting machines use a powerful plasma torch to cut and shape workpieces. The torch can produce heat up to 27,760 °C to melt away excess material. The only limitation to this method is that the workpiece must be electrically conductive, which includes the metals aluminum, brass, copper, steel, and stainless steel.

Precision CNC Machining by McCormick Industries

Before starting your CNC machining project, consider the required features, tolerances, materials, and performance of the finished components. McCormick Industries is a leading provider of precision CNC machining services including CNC swiss-style machining and CNC milling for small parts. We have delivered tailor-made CNC machining solutions to businesses throughout the industrial, aerospace, defense, and medical fields. Contact us to learn more or request a quote today.