Stainless steel is a preferred material for its corrosion-resistance, versatility, strength, low-maintenance properties, and aesthetic appeal. At McCormick Industries, we specialize in precision machined components. Our highly-skilled machinists deliver Swiss machining, CNC turning, and milling services for jobs requiring high levels of precision. We are ISO 9001:2015 certified and serve the medical, aerospace, industrial, defense, and other critical industries with expert machining.

Stainless steel is a preferred material for its corrosion-resistance, versatility, strength, low-maintenance properties, and aesthetic appeal. At McCormick Industries, we specialize in precision machined components. Our highly-skilled machinists deliver Swiss machining, CNC turning, and milling services for jobs requiring high levels of precision. We are ISO 9001:2015 certified and serve the medical, aerospace, industrial, defense, and other critical industries with expert machining.

Benefits of Stainless Steel

Stainless steel provides many advantages that make it a favored material for machining. These include:

- Corrosion resistance. The chromium content of stainless steel provides a non-reactive layer that prevents corrosion and allows the passive layer to heal when oxygen is present. Depending on the type of stainless steel, it can protect against acids, alkaline, chloride, and other corrosive atmospheres.

- Strength. The strength to weight ratio of stainless steel allows for the machining of lighter parts and components.

- Versatility. Stainless steel is available in many grades and can perform in extreme temperatures. This makes it compatible with a versatile set of machining and metallurgical processes, including cold hardening, heat curing, cutting, welding, and other forming methods.

- Surface. The surface of stainless steel allows for various finishes, coupled with its resistant properties. Machinists can create appealing products with stainless steel to suit many applications.

- Durability. Stainless steel is durable and requires little maintenance. It handles harsh conditions and has a longer lifespan than many other materials.

Machining Applications for Stainless Steel

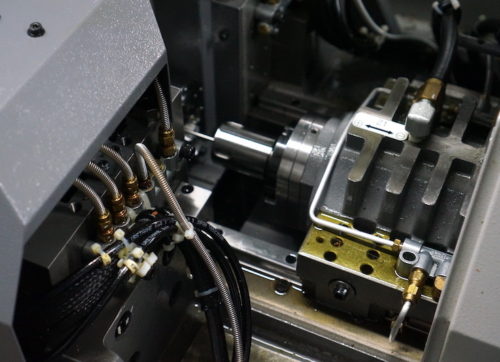

Stainless steel is an ideal material for various machining applications. At McCormick Industries, we offer Swiss machining as well as CNC milling and turning.

- Swiss machining. Swiss machining is a cost-effective method of machining stainless steel parts that can deliver either low or high volume production runs.

- CNC milling and turning. These computer-assisted machining methods are very popular for machining stainless steel. They provide tight tolerances, offer high levels of precision and repeatability, and are suitable for small or large production runs.

Types of Stainless Steel Used in Machining

There are various grades of stainless steel used in machining, with the most prevalent being 304 and 316. 304 stainless steel contains mostly iron with 18% chromium and 8% nickel. It delivers corrosion resistance, along with strength and formability. 304 is ideal for fittings, fasteners, piping, and gears. 303 stainless steel is more machinable than 304, but it’s relative weakness often makes 304 the preferred choice.

316 stainless steel has similar performance but offers improved corrosion resistance. Its composition includes molybdenum, an increased amount of nickel, and 16% chromium. This composition grants it the ability to withstand contact with acids and chlorides, making it an ideal choice for food service equipment, medical equipment, and industrial environments where acids or alkalis are present.

To further strengthen stainless steel, some grades are subject to heat treatments, which result in precipitation hardening of the material. One of the most used types of PH stainless steel is 17-4 PH stainless steel. The composition of this alloy contains between 15 – 17.5% of chromium. Its high mechanical strength and excellent resistance to corrosion make it ideal for industries such as petrochemical, marine, and aerospace.

Stainless Steel Machining Services From McCormick Industries

Stainless steel is a strong, flexible, and corrosion-resistant material, making it ideal for various parts and components. Available in many grades, stainless steel is receptive to a range of machining techniques to suit the needs of projects requiring high levels of precision. At McCormick Industries, we have been delivering precise CNC machining and Swiss-type machining of stainless steel grades such as 303, 304, 316, and 17-4 PH since 1996. We serve a variety of industries and strive to be a leading manufacturer of precision machined components.

For more information about our stainless steel machining services, or to get started on your next project, request a quote today.